Yaali / Yali : The meaning is a mythical creature seen in many South Indian sculptures. It may be portrayed as part lion, part elephant and part horse. Source: wikipedia

SOURCE CODE:

/*

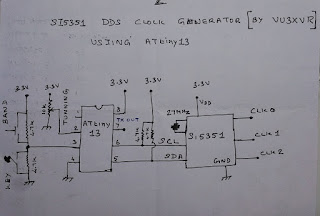

V U 3 X V R

Si5351 Clock Generator using ATtiny13

Programmed By : Ram Sankar Pillai

Date : 25-June-2018

Version : 1.0

Microcontroller Clock Speed = 1.2MHz using internal oscillator 9.6MHz/8 = 1.2MHz

8bit Timer0 overflow interrupt set to occur every 0.012Secons = 12millis

I2C data transfer using BIT-BANG method.

;********************************************************************************************

*/

.nolist

.include "tn13def.inc"

.list

;**** Ports ****

.equ SDAPORT = PORTB

.equ SDABIT = PORTB0

.equ SDADDR = DDRB

.equ SDAPIN = PINB

.equ SCLPORT = PORTB

.equ SCLBIT = PORTB1

.equ SCLDDR = DDRB

.equ SCLPIN = PINB

.equ txPORT = PORTB

.equ txBIT = PORTB2

.equ txDDR = DDRB

.equ txPIN = PINB

.equ keyPORT = PORTB

.equ keyBIT = PORTB4

.equ keyDDR = DDRB

.equ keyPIN = PINB

.equ b_dir = 0 ; transfer direction bit in i2cadr

.equ txFlagBit = 0 ; BIT0 of flagRegister SRAM # 128

.equ txDelayTimeFlagBit = 1 ; BIT1 of RX/TX switching delay time

;**** Registers ****

.def i2cdata = r17 ; I2C data transfer register

.def i2cadr = r18 ; I2C address and direction register

.def regNum = r20

.def regVal = r21

.def A = r16

;.def lastFreqVal = r17

;.def currentFreqVal = r18

;.def adcFreqByte1 = r19

;.def adcFreqByte2 = r20

;.def adcFreqByte3 = r21

.def btnCount = r22

.def currentBtnAdcVal = R23

.def tempFreqByte1 = R25

.def tempFreqByte2 = R26

.def tempFreqByte3 = R27

.def counter = R30

;********** Division def *****************

.def remainder1 = R0

.def remainder2 = R1

.def remainder3 = R2

.def remainder4 = R3

.def remainder5 = R4

.def remainder6 = R5

.def dividend1 = r16

.def dividend2 = r17

.def dividend3 = r18

.def dividend4 = r19

.def dividend5 = r20

.def dividend6 = r21

.def divisor1 = r24

.def divisor2 = r25

.def divisor3 = r26

.def divisor4 = r27

.def divisor5 = r28

.def divisor6 = r29

;********** Multiply def ******************

.def ANS1 = R0 ;64-Bit Answer

.def ANS2 = R1 ;

.def ANS3 = R2 ;

.def ANS4 = R3 ;

.def ANS5 = R4 ;

.def ANS6 = R5 ;

.def ANS7 = R6 ;

.def ANS8 = R7 ;

.def A1 = R16 ;Multiplicand

.def A2 = R17 ;

.def A3 = R18 ;

.def A4 = R19 ;

.def B1 = R20 ;Multiplier

.def B2 = R21 ;

.def B3 = R22 ;

.def B4 = R23 ;

.def C = R24 ;Loop Counter

.def freqByte1 = R8 ; do not change as it is not deleted by CLEAR ALL

.def freqByte2 = R9

.def freqByte3 = R10

;.def freqByte4 = R11

;___________________ START OF SRAM ADDRESS _____________________________________

.DSEG

aByte1: .byte 1

aByte2: .byte 1

bByte1: .byte 1

bByte2: .byte 1

bByte3: .byte 1

bByte4: .byte 1

b48bit1: .byte 1

b48bit2: .byte 1

b48bit3: .byte 1

b48bit4: .byte 1

b48bit5: .byte 1

b48bit6: .byte 1

p1Byte1: .byte 1

p1Byte2: .byte 1

p2Byte1: .byte 1

p2Byte2: .byte 1

p2Byte3: .byte 1

aTimes128B1: .byte 1

aTimes128B2: .byte 1

bTimes128b1: .byte 1

bTimes128b2: .byte 1

bTimes128b3: .byte 1

bTimes128b4: .byte 1

bTimes128byC: .byte 1

cTimes128bbyC1: .byte 1

cTimes128bbyC2: .byte 1

cTimes128bbyC3: .byte 1

cTimes128bbyC4: .byte 1

synth: .byte 1

flagRegister: .byte 1

lastFreqVal: .byte 1

currentFreqVal: .byte 1

temp1: .byte 1

temp2: .byte 1

.equ pllFreq = 810000000

.equ fr1 = 2970000+700

.equ fr2 = 7022300

;___________________________________________________________________________

.cseg

.ORG 0x000 RJMP onReset ;RESET VECTOR

.ORG 0x003 RJMP TIMER0_OVF

;___________________________________________________________________________

;*************************************

; TIMER 0 OVERFLOW INTERUPT ROUTINE *

;*************************************

TIMER0_OVF: ; 0.012 seconds; @1.2MHz clk; 12 milli second

PUSH A

INC counter

LDI A, 0b0010_0011 ; select ADC 03 = Tunning

RCALL readADC

STS currentFreqVal, A

LDI A,0x8B ;0x1F ;SET THE COMPARE REGISTER

OUT TCNT0,A

POP A

RETI

;___________________________________________________________________________

onReset:

LDI A, LOW(RAMEND)

OUT SPL, A

; LDI A,0b0000_0011 ; CLK 1/64

LDI A,0b0000_0101 ; CLK 1/1024

OUT TCCR0B, A

LDI A,0b0000_0010 ;ENABLE TIMER1 OVF, TIMER0_OVF

OUT TIMSK0, A

LDI A1,0x1F ;SET THE COMPARE REGISTER

OUT TCNT0, A

LDI A, 0b1000_0011 ; ADC clock should be 100 to 200KHz, Processor Clock Speed / 100k = x(round up to next division factor)

OUT ADCSRA, A ; ADC enable, ADC prescaler division factor 10

SEI

SBI txDDR, txBIT

CBI keyDDR, keyBIT

SBI keyPORT, keyBIT

;************ I2C INIT *********************

SBI SDADDR, SDABIT ; as output

SBI SCLDDR, SCLBIT ; as output

;************ PLL SETTINGS *******************

; Except PLL parameter #29, 32 all are ZERO only.

; 810MHZ DIV 27 MHz, then a=30; b=0; c=0

; becomes P1 = 3328 0b0000_1101_0000_0000

LDI regNum, 29

LDI regVal, 0b0000_1101

RCALL i2cSend

; LDI regNum, 32

; LDI regVal, 0b0000_1101

; RCALL i2cSend

; ******* One Time Settings *****************

LDI regNum, 16 ; CLK0 enable

LDI regVal, 0b0100_1101

RCALL i2cSend

; LDI regNum, 17 ; CLK1 disable

; LDI regVal, 0b0100_1101

; RCALL i2cSend

LDI regNum, 18 ; CLK2 enable

LDI regVal, 0b0100_1101

RCALL i2cSend

LDI regNum, 177 ; PLL Reset

LDI regVal, 0xAC

RCALL i2cSend

LDI regNum, 183 ; capacitor value

LDI regVal, 0b1101_0010

RCALL i2cSend

LDI regNum, 03 ; clock disable

LDI regVal, 0b1111_1110

RCALL i2cSend

;___________________ MAIN PROGRAM STARTS HERE ________________________________

main:

SBIS keyPIN, keyBIT

RJMP keyPressed

RJMP keyNotPressed

keyPressed:

LDS A, flagRegister

SBRC A, txFlagBIT ; skip next if txFlagBIT is 0. ie was in RX mode

RJMP checkFreqChange ; Do nothin, go to main loop

SBI txPORT, txBIT

LDI regNum, 03 ; clock enable

LDI regVal, 0b1111_1010

RCALL i2cSend

LDS A, flagRegister

SBR A, (1<<txFLagBIT) | (1<<txDelayTimeFlagBit)

STS flagRegister, A

RJMP checkFreqChange

keyNotPressed:

LDS A, flagRegister

SBRS A, txFlagBIT ; skip next if txFlagBIT is 1. ie was in TX mode

RJMP checkDelayTimeFlag ; Do nothing, go to main loop

LDI regNum, 03 ; clock enable

LDI regVal, 0b1111_1110

RCALL i2cSend

LDS A, flagRegister

CBR A, 1<<txFLagBIT

STS flagRegister, A

CLR counter

RJMP checkFreqChange

checkDelayTimeFlag:

LDS A, flagRegister

SBRS A, txDelayTimeFlagBit

RJMP checkFreqChange

CPI counter, 4 ; 350 millis delay

BRLO main ; keyChecked

CBI txPORT, txBIT

LDS A, flagRegister

CBR A, 1<<txDelayTimeFlagBit

STS flagRegister, A

; RJMP main

checkFreqChange:

LDS A, currentFreqVal

LDS R17, lastFreqVal

CP R17, A

BREQ main

STS lastFreqVal, A

CLI

LDS R17, currentFreqVal

CLR XL

CLR XH

mapStart:

INC XH

SUBI XL, -10

CPI XH, 25

BRLT ok

RJMP mapEnd

OK:

CP R17, XL

BRSH mapStart

mapEnd:

multiply8x8:

.def ansL = R0

.def ansH = R1

.def multiply8a = R26 ; A

.def multiply8b = R27 ; B

MOV multiply8a, XL ;currentFreqVal

LDI multiply8b, 100

LDI R28, 8 ; counter for multiply ; C

CLR ansH

MOV ansL, multiply8b

LSR ANSL

loopMul:

BRCC skipMul

ADD ANSH, multiply8a

skipMul:

ROR ANSH

ROR ANSL

DEC R28

BRNE loopMul

;************************ CLK 1 **************************

LDI tempFreqByte1, LOW(fr1)

LDI tempFreqByte2, byte2(fr1)

LDI tempFreqByte3, byte3(fr1)

MOV freqByte1, tempFreqByte1

MOV freqByte2, tempFreqByte2

MOV freqByte3, tempFreqByte3

PUSH ansL

PUSH ansH

ADD freqByte1, ansL

ADC freqByte2, ansH

LDI A, 0

ADC freqByte3, A

LDI A, 42 ; setting frequency on CLK0

STS synth, A

RCALL arithmatic

;********************* CLK 2 *******************************

POP ansH

POP ansL

LDI tempFreqByte1, LOW(fr2)

LDI tempFreqByte2, byte2(fr2)

LDI tempFreqByte3, byte3(fr2)

MOV freqByte1, tempFreqByte1

MOV freqByte2, tempFreqByte2

MOV freqByte3, tempFreqByte3

SUB freqByte1, ansL

SBC freqByte2, ansH

LDI A, 0

SBC freqByte3, A

LDI A, 58 ; ; setting frequency on CLK2

STS synth, A

RCALL arithmatic

SEI

rjmp main

;______________________ ENF OF MAIN PROGRAM ____________________________

;************************************************

; Subprogram delay *

;************************************************

;delay:

; CLR counter

;delayNotFinished:

; CP counter, A

; BRLO delayNotFinished

;RET

;_________________________________________________________________________

readADC:

OUT ADMUX, A ; AVcc, left adjust( we need just ADCH only), ADC0

SBI ADCSRA, ADSC ; start ADC conversion

keep_pooling:

SBIS ADCSRA, ADIF ; look for ADC conversion finish flag ADIF

RJMP keep_pooling

SBI ADCSRA, ADIF

IN A, ADCH ; load ADCH into A

RET

;_________________________________________________________________________

;************************************************

; Set Frequencey subroutines *

;************************************************

setFrequency:

; P1 Registers

; #46 #45 #44

; MS0_P1[0:7], MS0_P1[15:8], MS0_P1[17:16]

; p1Byte1 p1Byte2, p1Byte3

; when freq is > 2MHz the P1 will be less than 16bit, hence

; bit 17:16 will become zero.

; #44 also contains R divider value, which is Zero in our case

; P2 Registers

; #49 #48 #47

; MS0_P2[0:7], MS0_P2[15:8], MS0_P2[19:16] [3:0]

; p2Byte1 p2Byte2, p2Byte3

; P3 registers

; #43 #42 #47

; MS0_P3[0:7], MS0_P3[15:8], MS0_P3[19:16] [7:4]

; p1Byte1 p1Byte2, p1Byte3

LDS regNum, synth ; #42, #50, #58

LDI regVal, 0b1111_1111

RCALL i2cSend

INC regNum ; #43

LDI regVal, 0b1111_1111

RCALL i2cSend

INC regNum ; #44 this parameter is always ZERO

; LDI regNum, 44

; LDI regVal, 0x00

; RCALL i2cSend

INC regNum ; #45

LDS regVal, p1Byte2

RCALL i2cSend

INC regNum ; #46

LDS regVal, p1Byte1

RCALL i2cSend

INC regNum ; #47

LDS A, p2Byte3

ORI A, 0b1111_0000

MOV regVal, A

RCALL i2cSend

INC regNum ; #48

LDS regVal, p2Byte2

RCALL i2cSend

INC regNum ; #49

LDS regVal, p2Byte1

RCALL i2cSend

RET

;*_____________________________________________________________

i2cSend:

ldi i2cadr,0xc0;+i2cwr ; Set device address and write

rcall i2c_start ; Send start condition and address

MOV i2cdata,regNum ; Write word address (0x00)

rcall i2c_do_transfer ; Execute transfer

MOV i2cdata,regVal ; Set write data to 01010101b

rcall i2c_do_transfer ; Execute transfer

rcall i2c_stop ; Send stop condition

RET

;_____________________________________________________________

i2c_start:

mov i2cdata,i2cadr ; copy address to transmitt register

sbi SDADDR,SDABIT ; force SDA low

rcall i2cDelay ; quarter period delay

i2c_write:

sec ; set carry flag

rol i2cdata ; shift in carry and out bit one

rjmp i2c_write_first

i2c_write_bit:

lsl i2cdata ; if transmit register empty

i2c_write_first:

breq i2c_get_ack ; goto get acknowledge

sbi SCLDDR,SCLBIT ; force SCL low

brcc i2c_write_low ; if bit high

nop ; (equalize number of cycles)

cbi SDADDR,SDABIT ; release SDA

rjmp i2c_write_high

i2c_write_low: ; else

sbi SDADDR,SDABIT ; force SDA low

rjmp i2c_write_high ; (equalize number of cycles)

i2c_write_high:

rcall i2cDelay ; half period delay

cbi SCLDDR,SCLBIT ; release SCL

rcall i2cDelay ; half period delay

rjmp i2c_write_bit

i2c_get_ack:

sbi SCLDDR,SCLBIT ; force SCL low

cbi SDADDR,SDABIT ; release SDA

rcall i2cDelay ; half period delay

cbi SCLDDR,SCLBIT ; release SCL

i2c_get_ack_wait:

sbis SCLPIN,SCLBIT ; wait SCL high

;(In case wait states are inserted)

rjmp i2c_get_ack_wait

clc ; clear carry flag

sbic SDAPIN,SDABIT ; if SDA is high

sec ; set carry flag

rcall i2cDelay ; half period delay

RET

;*_____________________________________________________________

i2c_do_transfer:

sbrs i2cadr,b_dir ; if dir = write

rjmp i2c_write ; goto write data

i2c_stop:

sbi SCLDDR,SCLBIT ; force SCL low

sbi SDADDR,SDABIT ; force SDA low

rcall i2cDelay ; half period delay

cbi SCLDDR,SCLBIT ; release SCL

rcall i2cDelay ; quarter period delay

cbi SDADDR,SDABIT ; release SDA

rcall i2cDelay ; half period delay

RET

;*_____________________________________________________________

i2cDelay:

NOP

NOP

NOP

NOP

RET

;_____________________________________________________________

;******************************************************

; P1, P2, P3 Arithmatic Functions *

;******************************************************

arithmatic:

RCALL clearAll

ldi dividend1, low(pllFreq) ;1 LS-Byte

ldi dividend2, byte2(pllFreq) ;1

ldi dividend3, byte3(pllFreq) ;1

ldi dividend4, byte4(pllFreq) ;1 MS-Byte

MOV divisor1, freqByte1 ;1 LS-Byte

MOV divisor2, freqByte2 ;1

MOV divisor3, freqByte3 ;1

CLR divisor4;, freqByte4 ;1 MS-Byte

; this is a + b/c = PLLFreq / Freq

rcall divideU32byU32r ;- result (dividend4-dividend1) should be 1000000 (1000000.49)

STS aByte1, dividend1 ; hold value of " a "

STS aByte2, dividend2

MOV r12, remainder1

MOV r13, remainder2

MOV r14, remainder3

MOV r15, remainder4

RCALL clearAll ; aByte & bByte both TESTED OK

;______________________________________________________________________________

; remainder multiply 0xFFFFF

MOV a1, r12

MOV a2, r13

MOV a3, r14

MOV a4, r15

ldi b1, low(0xFFFFF)

ldi b2, byte2(0xFFFFF)

ldi b3, byte3(0xFFFFF)

RCALL multiply32x32

MOV r12, ans1

MOV r13, ans2

MOV r14, ans3

MOV r15, ans4

STS b48bit5, ans5

STS b48bit6, ans6

RCALL clearAll

;______________________________________________________________________________

; divide by frequency

MOV dividend1, r12

MOV dividend2, r13

MOV dividend3, r14

MOV dividend4, r15

LDS dividend5, b48bit5

LDS dividend6, b48bit6

MOV divisor1, freqByte1

MOV divisor2, freqByte2

MOV divisor3, freqByte3

CLR divisor4;, freqByte4

rcall divideU32byU32r

STS bByte1, dividend1 ; hold value of " b "

STS bByte2, dividend2

STS bByte3, dividend3

STS bByte4, dividend4 ; holds b final value

RCALL clearAll

;______________________________________________________________________________

; b times 128

LDS A1, bByte1

LDS A2, bByte2

LDS A3, bByte3

LDS A4, bByte4

LDI B1, 128;LOW(128)

rcall multiply32x32 ; this is = b * 128 ; 32bit answer

STS bTimes128b1, ANS1

STS bTimes128b2, ANS2

STS bTimes128b3, ANS3

STS bTimes128b4, ANS4

RCALL clearAll

;______________________________________________________________________________

LDS dividend1, bTimes128b1

LDS dividend2, bTimes128b2

LDS dividend3, bTimes128b3

LDS dividend4, bTimes128b4

ldi divisor1, low(0xFFFFF) ;1 LS-Byte

ldi divisor2, byte2(0xFFFFF) ;1

ldi divisor3, byte3(0xFFFFF) ;1

rcall divideU32byU32r ; this result is = 128 * b / 1048575

STS bTimes128byC, dividend1

RCALL clearAll

;______________________________________________________________________________

; now it = 128 * a

LDS A1, aByte1

LDS A2, aByte2

LDI B1, 128;LOW(128)

RCALL multiply32x32 ; i'm getting 14720 ; we are interested in ans1 & ans2 only = 16bit

MOV r12, ans1

MOV r13, ans2

RCALL clearAll

;______________________________________________________________________________

MOV add1L, r12

MOV add1H, r13

LDS add2L, bTimes128byC

CLR add2H

add add1l, add2l ;Add low bytes

adc add1h, add2h

STS temp1, add1L

STS temp2, add1H

RCALL clearAll

;______________________________________________________________________________

LDS sub1L, temp1

LDS sub1H, temp2

LDI sub2L, LOW(512)

LDI sub2H, BYTE2(512)

sub sub1l,sub2l ;Subtract low bytes

sbc sub1h,sub2h ;Add high byte with carry

STS p1Byte1, sub1L

STS p1Byte2, sub1H ; this hold P1 Value.

RCALL clearAll

;______________________________________________________________________________

; now it = 128 * b

LDS A1, bByte1

LDS A2, bByte2

LDS A3, bByte3

LDS A4, bByte4

LDI B1, LOW(128)

; LDI B2, BYTE2(128)

RCALL multiply32x32

STS bTimes128b1, ANS1

STS bTimes128b2, ANS2

STS bTimes128b3, ANS3

STS bTimes128b4, ANS4

RCALL clearAll

;______________________________________________________________________________

; now it = C *( 128 * b/c )

LDS A1, bTimes128byC

LDI B1, LOW(0xFFFFF)

LDI B2, BYTE2(0xFFFFF)

LDI B3, BYTE3(0xFFFFF)

RCALL multiply32x32

MOV r12, ans1

MOV r13, ans2

MOV r14, ans3

MOV r15, ans4

RCALL clearAll

;______________________________________________________________________________

; Now subtraction of (128*b) - (c* 128*b/c)

LDS sub1byte1, bTimes128b1

LDS sub1byte2, bTimes128b2

LDS sub1byte3, bTimes128b3

LDS sub1byte4, bTimes128b4

MOV sub2Byte1, r12

MOV sub2Byte2, r13

MOV sub2Byte3, r14

MOV sub2Byte4, r15

SUB sub1byte1,sub2byte1 ;Add the lower bytes together

SBC sub1byte2,sub2byte2 ;Add the second bytes and include carry bit

SBC sub1byte3,sub2byte3 ;Add the third bytes and include carry bit

SBC sub1byte4,sub2byte4 ;Add the fourth bytes and include carry bit

STS p2Byte1, sub1byte1 ; this on holds P2 values.

STS p2Byte2, sub1byte2

STS p2Byte3, sub1byte3

RCALL setFrequency

RET

;______________________________________________________________________________

;************************************************************

; CLEAR ALL REGISTERS *

;************************************************************

clearAll: ; These are registers used in arithmatic functions.

CLR R0

CLR R1

CLR R2

CLR R3

CLR R4

CLR R5

CLR R6

CLR R7

CLR R16

CLR R17

CLR R18

CLR R19

CLR R20

CLR R21

CLR R22

CLR R23

CLR R24

CLR R25

CLR R26

CLR R27

CLR R28

CLR R29

RET

;**** add16 Register Variables

.def add1l = r16

.def add1h = r17

.def add2l = r18

.def add2h = r19

;sub32 Register Variables

.DEF sub1byte1 = R16 ;To hold low byte of value1

.DEF sub1byte2 = R17 ;To hold second byte of value1

.DEF sub1byte3 = R18 ;To hold third byte of value1

.DEF sub1byte4 = R19 ;To hold fourth byte of value1

.DEF sub2byte1 = R20 ;To hold low byte of value2

.DEF sub2byte2 = R21 ;To hold second byte of value2

.DEF sub2byte3 = R22 ;To hold third byte of value2

.DEF sub2byte4 = R23 ;To hold fourth byte of value2

;* "sub16" - Subtracting 16-bit registers

.def sub1l = r16

.def sub1h = r17

.def sub2l = r18

.def sub2h = r19

;************************************************************

; Start of 32 % 32 bit division *

; http://www.avrfreaks.net/comment/4819#comment-4819 *

;************************************************************

; Dividend will hold the integer result

divideU32byU32r:

ldi counter,49 ;1 init loop counter

divideU32byU32ra:

sec ;1 set carry

divideU32byU32rb:

rol dividend1 ;1 shift left dividend

rol dividend2 ;1

rol dividend3 ;1

rol dividend4 ;1

rol dividend5

rol dividend6

dec counter ;1

brne divideU32byU32rc ;1/2

ret ;4

divideU32byU32rc:

rol remainder1 ;1

rol remainder2 ;1

rol remainder3 ;1

rol remainder4 ;1

rol remainder5

rol remainder6

sub remainder1,divisor1 ;1 rem -= divisor

sbc remainder2,divisor2 ;1

sbc remainder3,divisor3 ;1

sbc remainder4,divisor4 ;1

sbc remainder5,divisor5

sbc remainder6,divisor6

brcc divideU32byU32ra ;1/2 if res < 0

add remainder1,divisor1 ;1 restore remainder

adc remainder2,divisor2 ;1

adc remainder3,divisor3 ;1

adc remainder4,divisor4 ;1

adc remainder5,divisor5

adc remainder6,divisor6

clc ;1 clear carry

rjmp divideU32byU32rb ;2

;************************************************************

; Start of 32 x 32 bit multiplication *

;************************************************************

multiply32x32:

; https://sites.google.com/site/avrasmintro/home/2b-basic-math

MUL3232:

SUB ANS8,ANS8 ;Clear ANS8 and Carry Flag

MOV ANS1,B1 ;Copy Multiplier to Answer

MOV ANS2,B2 ;

MOV ANS3,B3 ;

MOV ANS4,B4 ;

LDI C,33 ;Set Loop Counter to 33

LOOP:

ROR ANS4 ;Shift Multiplier to right

ROR ANS3 ;

ROR ANS2 ;

ROR ANS1 ;

DEC C ;Decrement Loop Counter

BREQ DONE ;Check if all bits processed

BRCC SKIP ;If Carry Clear skip addition

ADD ANS5,A1 ;Add Multipicand into Answer

ADC ANS6,A2 ;

ADC ANS7,A3 ;

ADC ANS8,A4 ;

SKIP:

ROR ANS8 ;Shift high bytes of Answer

ROR ANS7 ;

ROR ANS6 ;

ROR ANS5 ;

RJMP LOOP

DONE:

RET

;************************ END of 32 x 32 bit Multiplication ************************